Industrial PCs in stainless steel housing for the hygienic environment

FORSIS industrial PCs in stainless steel housing are of great importance for the production of food and pharmaceutical products. It allows no compromises - neither in terms of hygiene in the manufacturing process nor in the traceability of the products. The demands on the production process are therefore extremely high.

The requirements for the data acquisition devices used are just as high - the FORSIS industrial PCs in a stainless steel housing.

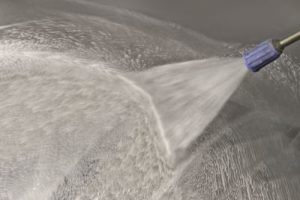

Uncompromisingly tight! Industrial PC in stainless steel housing

Can your data acquisition devices in the production environment withstand a hard jet of water, powerful cleaning agents or extremely low temperatures without additional housing?

The industrial PCs in the stainless steel housing of the FORSIS EXPERT series work absolutely reliably even under extreme conditions.

Location and protection of the cable entry is the most important consideration. The result: minimal installation and maintenance costs.

With FORSIS as your holistic solution partner, you are on the safe side in every respect - regardless of whether it is a matter of robust stainless steel PCs or mobile stainless steel workstations. Standard-compliant stainless steel design and the right protection class ensure maximum availability with minimal cleaning and maintenance costs.

Core competencies of industrial PCs in stainless steel housing

The stainless steel PC of the EXPERT SBC series has the following features:

- Cable feed from behind, sunk into cassette

- Connection area protected by various covers

- Protection class IP69 on the front, connection depending on protection variant

- Analog resistive touchscreen technology, can be operated with gloves, shatter protection due to the front film in front of the glass carrier

- Compact design due to the very low device depth

- RFID readers can be integrated into the housing or attached

The EXPERT SBC series of stainless steel PCs has been expanded to include a multi-touch variant with capacitive touchscreen technology in the 21.5-inch version.

The new model presents itself in a new design without losing functionality. The smooth, almost gapless surface offers no point of contact for dirt - see for yourself!

The EXPERT SE series stainless steel PC has the following features:

- Cable feed from below, connections sunk into cassette

- Type of protection on the front according to EN60529 IP69

- On the connection side, depending on the selected interface protection, also up to IP69

- LCD variants up to 21.5" with FHD resolution in 16:9 format

- Analog resistive touchscreen technology can be operated with gloves

- Shatter protection due to the front film in front of the glass carrier

- Temperature range -5°C to 50°C

- Frozen variant: From the 17" device variant, it is possible to integrate a 400 watt heater including control. The temperature range then increases to -30°C to 50°C.

The EXPERT BS series stainless steel PC has the following features:

- Cable feed from below in the form of BINDER connectors

- Protected by the all-round impact protection

- Protection class IP69 on the front and on the connection side, sockets that are not required must be closed

- FORSIS BINDER connector: The PC interfaces are routed to the underside of the device using adapter boards. This is where the direct plug-in contact is made

- All basic interfaces are always available - assignment corresponds to the SEMA assignment

- The interfaces can be expanded using three adapter boards that can be combined at will

The hygiene requirements for operating equipment for the pharmaceutical industry, the food processing trade and the food industry are extremely high. The basic requirement is the use of stainless steel as the housing material and food-approved materials in the area of the seal.

In addition to the stainless steel PC, which is the focus, the feedback can also be seen as a whole, i.e. the mechanical fixation of the devices in the overall system and their supplementation or completion by peripheral components.

FORSIS also offers stationary printer stations or protective housings for wall mounting.

Would you like to know in which environment you can use our stainless steel PCs? Under the heading "Reference reports in a hygiene-sensitive environment" some of our customers report on their practical experiences with FORSIS products in their operational environment.

Curious? Then read on!

In addition to numerous products such as the stainless steel PCs for the hygiene-sensitive industry, FORSIS offers other approaches to data acquisition.

You can find more solutions and information here.