Forklift terminal resistive

The resistive forklift terminal of the MOBILE series

FORSIS offers three different variants in the field of mobile forklift terminals, each of which is adapted to specific customer requirements. Because forklift terminals should always make do with the minimum external dimensions, but at the same time offer a maximum LCD viewing area.

The resistive forklift terminal called MOBILE has been designed with an analogue resistive touch and is available in the LCD sizes 10", 12" and 15". This means that the applications are displayed on the LCD as large as possible without blocking the driver's field of vision restricted - because safety is our top priority.

The touchscreen technology of the resistive forklift terminal is based on ELO's proven 5-wire resistance technology and is called AccuTouch. This technology is designed for applications that require the highest reliability, input flexibility and resistance to contamination.

The Accutouch screens use a glass plate with a uniform resistive coating. A thick polyester cover sheet is stretched over the glass surface and features small, clear isolating dots that produce a resistance change when pressed, that is, when an input is made.

The main difference between mobile devices and stationary ones is their power supply, energy management and vibration resistance.

- The degree of protection of the resistive forklift terminal [EN60529] is IP65 on the front and, depending on the type and version, IP54 on the connection side

- Approvals: CE, FCC

- Vibration and shock test according to DIN EN 60721-3-5/5M3

- Wireless connection: IEEE 802.11 ac/g/n

- Bluetooth interface if WLAN adapter is integrated

- Standard temperature range: -20°C to 50°C due to the chosen components

- Humidity: 0-90% non-condensing

- Technology: AccuTouch 5-wire resistance sensor

- Input methods: fingers, styluses, pens, gloves, etc.

- Light transmission: HL products: 80%; +-5% at 550 nm wavelength

- Cover glass thickness: T = 1.8mm

- Surface treatment: clear

- Lifespan: AccuTouch Zero-Bezel. Each touchscreen meets stylus hardness 4H according to ASTM D3363

- Sealability: NEMA4, NEMA12 and IP65 sealing possible

- Resolution: Touch point density according to controller resolution 4096 x 4096

- Positioning accuracy: Standard deviation error <0.080 (2 mm)

- Operating temperature: -10°C to 60°C

- Storage temperature

High temperature storage: 70°C for 240h - after 24h room temperature and test

Low temperature storage: -40°C for 240h after 24h room temperature and test - Humidity: 90% relative humidity at max. 50°C

Mechanical structure of the resistive forklift terminal

- The housing of the resistive forklift terminal is made of steel / aluminum sheet metal parts. These are powder coated on the outside and galvanized on the inside

- The device design is compact and vibration-proof

- The resistive forklift terminal has minimal cabling and no mechanically moving components

- The heat dissipation at the resistive forklift terminal takes place via the rear ten millimeter thick mounting plate, all heat-generating components dissipate here

- At the same time, this plate also offers attachment preparation in VESA 100 format

Forklift terminal resistive - specifications

- The degree of protection of the resistive forklift terminal [EN60529] is IP65 on the front and, depending on the type and version, IP54 on the connection side

- Approvals: CE, FCC

- Vibration and shock test according to DIN EN 60721-3-5/5M3

- Wireless connection: IEEE 802.11 ac/g/n

- Bluetooth interface if WLAN adapter is integrated in the resistive forklift terminal

- Standard temperature range: -20°C to 50°C due to the chosen components

- Humidity: 0 – 90% (non-condensing)

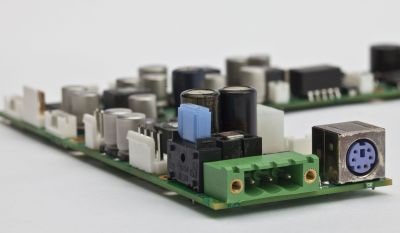

The control unit of the resistive forklift terminal

The touchscreens of the resistive forklift terminal have an extremely long service life. The AccuTouch series determines the X and Y coordinates on a stable under glass plate. For this reason, the touchscreens with resistance sensors ensure an extremely long service life - they are designed for a frequency of use of more than 35 million touches.

The bottom glass pane is covered with a plastic film. In this way, if the panel breaks, no glass splinters can get in the direction of the operator. It can be operated with gloves, styluses, pens, etc. The touchscreen is calibration-resistant and insensitive to surface moisture.

The resistive forklift terminal's touchscreen can also be sealed against contamination to NEMA4/4x/12 and IP65 standards. Each touchscreen meets stylus hardness 4H according to ASTM D3363. Homologations: UL, cUL, TUV, CE and FCC Class A.

Dimensions of the resistive forklift terminal of the MOBILE series

Below you will find the external dimensions of the resistive forklift terminal of the MOBILE series. All dimensions in mm.

- Variant 1000

LCD size: 10.4"

Width: 267 / Height: 236* / Depth: 70

Weight: 3.3 kg - Variant 1200

LCD Size: 12.1"

width: 300 / height: 266* / depth: 70

Weight: 5.2 kg - Variant 1500**

LCD Size: 15"

Width: 365 / Height: 305 / Depth: 79

Weight: 7.1 kg

* Due to the impact-resistant antenna housing with IP65 protection class, the housing height of the resistive forklift terminal increases by 60mm

** Only available with analog resistive touchscreen technology

The difference between the models in the forklift terminal series is not just the touchscreen technology, but also the connection rows and the associated device depth.

WLAN connection according to IEEE802.11 ac/g/n combined with Bluetooth V4.0

- The resistive forklift terminal offers a MINI PCIe slot - free choice of WLAN adapter

- FORSIS offers its own antenna for all device series.

The antenna consists of three differently oriented individual antenna systems. Depending on the number of antenna connections of the WLAN card used, these can be combined as desired - The antennas work in the 2.4 GHz - 5 GHz range. This means that Bluetooth signals could also be placed on these antennas, especially with the combi WLAN adapter

- Wi-Fi 802.11 ac/g/n standard and Bluetooth V4.0 are supported

- In addition to implementing the n standard, our goal was to develop a robust antenna with protection class IP65

Cable lock / strain relief - connection side

All cable connections of the resistive forklift terminal are on the back and go down. Four screw terminals are mounted on a carrier to relieve strain on the cables. This carrier is detachable by a secured knurled screw.

In concrete terms, this means: Simple and one-time assembly of the cables. The cable carrier remains in place even if the device is replaced.

Protective cover - rear view

To protect the plug connection, the entire connection side of the resistive forklift terminal can be closed with a protective cover. The cover is secured by two studs and two thumbscrews.

"Wir beantworten gerne Ihre Fragen."

Integrated or external UPS unit on the resistive forklift terminal

The optional AKKU unit is used for short-term support of the supply voltage. With the MOBILE 1000, the BATTERY unit is external, from the MOBILE 1200 variant it is integrated in the device. The same applies to the MOBILE MT and MOBILE MF series.

- The battery works in standby mode and serves as a support in the event of short-term dips

- It bridges power failures for up to five minutes or depending on the battery type

- The monitoring and charging electronics enable a controlled, time-controlled shutdown

Below you will find the technical basics on which the resistive forklift terminal is based. You will find this basic technology as a basis in all devices of the MOBILE series and is responsible for the successful and error-free operation of the forklift terminals.

- Wide range input of the supply voltage from 10 to 30 volts DC, expandable with external DC/DC converters up to 90V DC

- Protective circuit for voltage peaks with integrated Zypressor diode from 35V DC

- Minimization of power consumption to the lowest values - the power consumption in operation is only approx. 25 watts, in standby even less than one watt

- The DC/DC converter unit can be loaded up to about 65 watts

- The housing of the resistive forklift terminal is divided into a "CPU unit" and the "HMI unit"

- The CPU unit is made of sheet steel - the motherboard is screwed firmly to the housing. This part of the housing is powder-coated on the outside and galvanized on the inside

- The HMI (Human Man Interface) includes the LCD and the touch screen. The housing of the front unit is made of powdered aluminum. Depending on the version, the touchscreen is glued in from the front or the back

- The device structure of the resistive forklift terminal is compact and vibration-proof

- Minimized wiring and no mechanically moving components

- Heat dissipation takes place via the rear 10 mm thick mounting plate, all heat-generating components are mounted directly here and dissipate the heat generated directly here

- At the same time, this plate also offers attachment preparation in VESA100 format